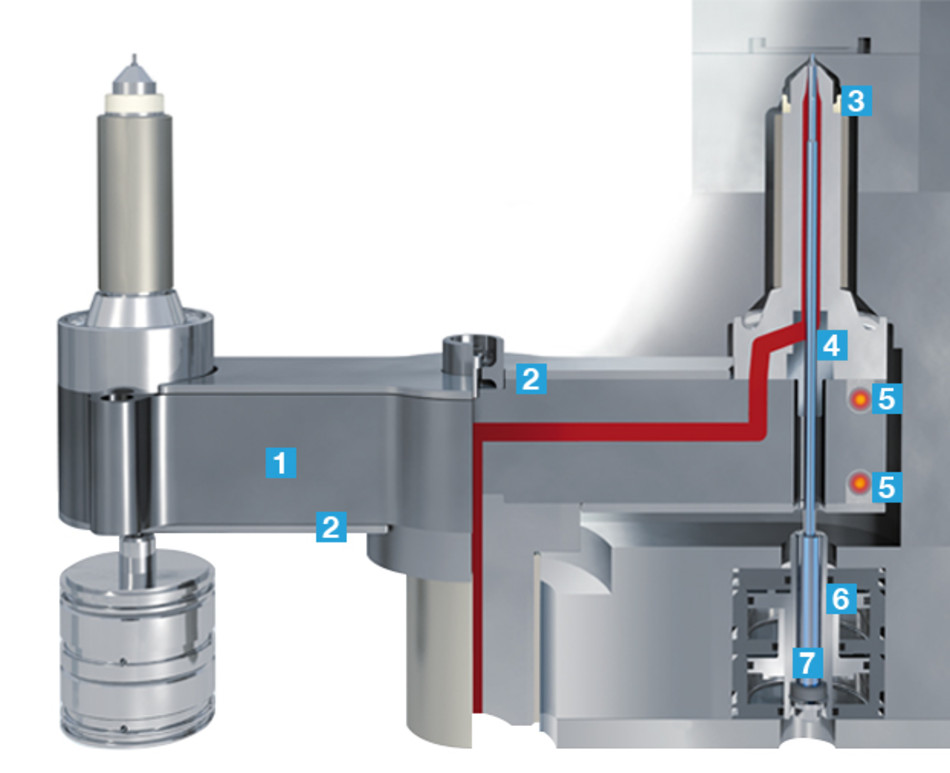

Because the needle drive is positioned in the clamping plate the total height of the system is similar to a normal hot runner system see figure 7.

Electric valve gate hot runner system.

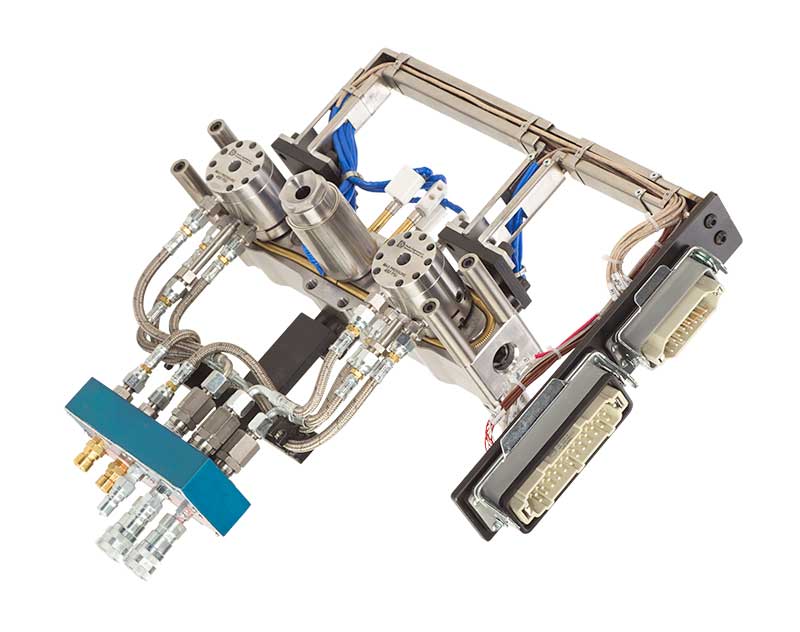

When the valve gates are fired oil is used from the hydraulic accumulator.

The standard valve gate is of importance when a low system height is required.

The pump then rests until oil is needed again.

The right device to reduce flowmarks in sequential filling.

Within these groups valve gate hot runners are available in pneumatic hydraulic and electric models each of which has its own advantages and disadvantages for certain types of applications.

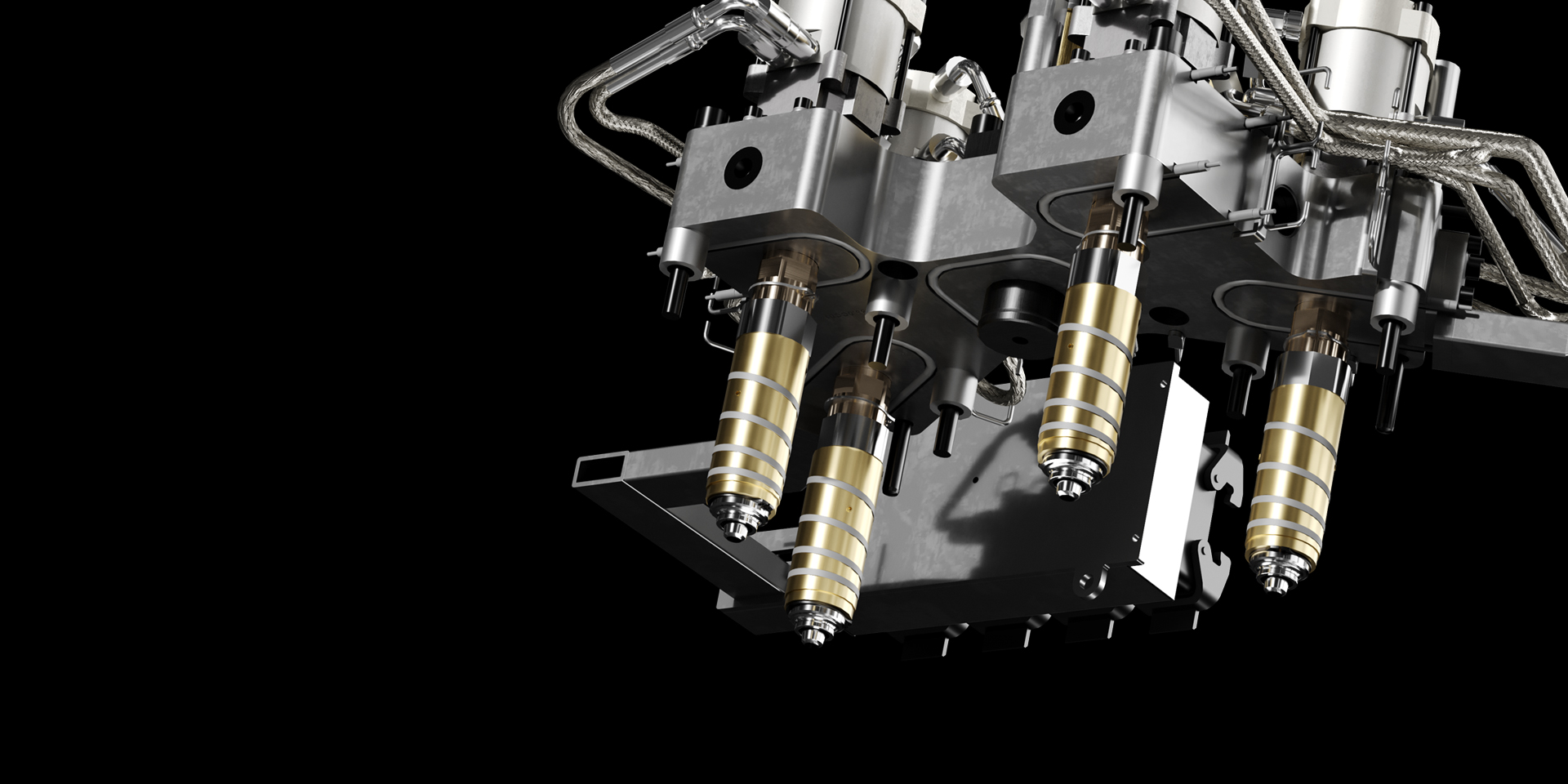

This technology is now available on all synventive hot runner nozzle sizes.

Standard injection gated manifolds.

Hydraulic valve gate sequencer.

Egate electric valve gate hot runner systems feature patented technology to precisely control each valve pin s position acceleration velocity and stroke allowing processors the unique ability to control the flow rate out of each nozzle gate at any time during the fill process.

Pneumatic valve gate sequencer.

Avoid the costly maintenance and downtime associated with traditional valve gate designs.

Individual stem actuation and plate actuation.

Egate electric valve gate hot runner systems feature patented technology to precisely control each valve pin s position acceleration velocity and stroke allowing processors the unique ability to control the flow rate out of each nozzle gate at any time during the fill process.

Today the mold masters hot runner product line has expanded and represents the broadest selection of hot runner products from any manufacturer.

Electric valve gate system.

Once the pressure in the accumulator is below set point the hydraulic pump replenishes the accumulator.

Embossed doors not embossed bumpers luggage.

Valve gate hot runners can be broken down into two main groups.

Flexspeed technology has been developed to avoid the generation of flowmarks on the part surface generated by the instability of the plastic flow front in sequential moulding.

Dual capability valve gate sequencer.

This technology is recommended for medium to large size parts obtained through sequential moulding such as.

Compatible with both commodity and engineering grate resins accu valve meets the demanding needs of many medical packaging personal care and many other applications.

We ve come a long way since that first design.

This control is based on pump on demand technology.